L.O.A. 25’

L.W.L 20’

Beam 8’

Draft 4’

Disp. 4000 lbs.

Ballast 1700 lbs.

Sail Area 286 sq. ft.

Main Sail hoist (P)== 25 ft

Boom (E)= 11ft.

Many Owners have got to extraordinary lengths to restore their Cal 25’s. The Restorations Menu has the details of what it takes to restore a Cal 25!

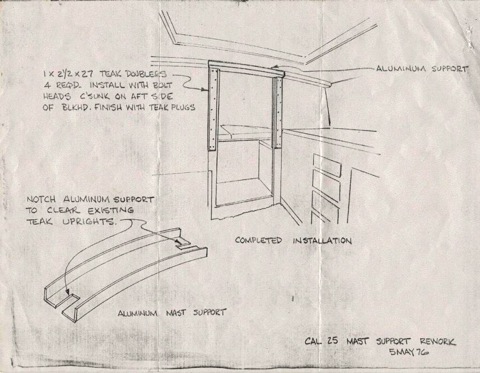

Mast Base Repair

A good example of a sagging beam, a common occurrence for many Cal 25's. but one that is fixable.

Below is one approach to repair. Another more complete set of documents was sent in by former Cal 25 owner Dave Godwin who still sails in the Annapolis fleet. Take a look at both methods and decide which one will work for you. They are available at here.

N.B. Any of the methods, ideas or Techniques for mast base repair are used at your own risk. By reading and using this website you agree to hold harmless the owners of this website.

Much thanks to Scott Smith who posted the article below on the boards Jan 08th and then sent in a (Below) (click the link for a printable page of the drawing).

1. Remove privacy curtain & clips.

2. Remove mast wiring cover if on underside of headliner. Note: the aluminum support fits over the existing laminated plywood beam. The wiring must be recessed into the laminated beam or rerouted to avoid its being crushed upon installation of the aluminum support.

3. The aluminum support will extend athwartships approx. to the outboard edges of the vertical teak posts as shown in the sketch. Using the aluminum support as a template, remove the overhead teak trim for the length of the support. Radius the sawcut edges.

4. Position the aluminum support in line athwartships with the teak trim, scribe the portions of the aluminum support to be removed on both sides to clear the teak posts. See sketch.

5. Notch the aluminum support and check fit.

6. Using a jack with a suitable support underneath so as not to damage the cabin sole. Position the aluminum support and jack it up until the contour of the deck matches the contour of the aluminum support.

7. With the aluminum support in this position, locate the teak doublers over the existing teak uprights on FWD and AFT sides of the bulkhead, see sketch.

8. Apply glue to the mounting surfaces and with the doublers securely clamped in position, drill the bolt holes for 1/4" flat head bolts using the pilot holes predrilled in 2 of the 4 doublers.

9. Countersink the bolt heads on the FWD side of the bulkhead, deep enough to plug the holes with teak plugs. Install the bolts using acorn nuts on AFT side.

10. Plug the holes, reinstall clips for curtain track using sheet metal screws supplied.

CAL 25 Mast Support Rework Bill of Materials PRICES ARE FROM 1978!!!

No. Reqd. Description

1 Aluminum Support $59.85

4 Teak doubler - 1 x 2-1/2 x 27 $16.64

24 1/4 - 20 x 3 SS FHMS

24 Flat washer, SS, 1/4

24 Acorn nut, 1/4 - 20 SS

4 Screw SS RHSMS #6 x 1/2

24 Teak plug 1/2" diameter

1/2 pt Glue - Franklin Yellow

1 7/16" dia drill 1 1/4" dia drill 1 1/2" dia C'sink (1/4" drill)

1 Plastic squeeze bottle

See the Mastbase 2 Page